-

Email Us

Email: [email protected]

-

Mob/WhatsApp

+86 18037198058

Refractory Material Products

Our advantage refractory for you

Refractory manufacturer, optimal solutions for you.

Our Client

All over the world

About Us

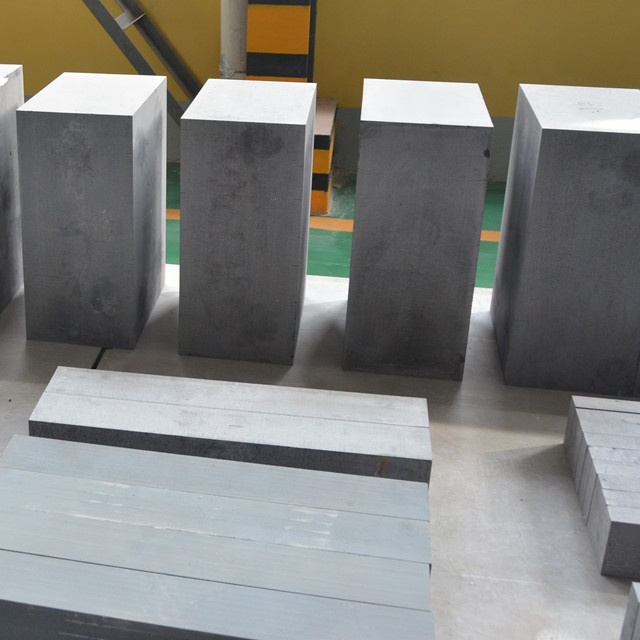

Yuhua Refractory was founded in 2006, located in Chaohua Industrial Area, Xinmi City, Henan Province, P. R. China. We are a comprehensive modern enterprise integrating production & research, design, product technical solutions and the general contracting and operation of refractory materials.

Email: Email: [email protected]

Mob/WhatsApp/Wechat/Skype: +86 18037198058

Why Choose Us?

Service

Solution

We provides one-to-one solutions by your inquiry.

Manufacturer

True refractory manufacturer, provide OEM/ODM.

Standardization

Create value for you through standard quality management.

Factory price

Relying on the strict control of production, we can give you competitive price.

ISO9001

As ISO9001 ensuring high quality and continuous improvement of process and product quality.

Shipping

Through years of precipitation, we can ship to you with lower freight, no matter where you are.

Case&News

Know Yuhua every day

-

20

2024-12

The most energy-consuming part of glass production equipment is the glass kiln, which accounts for more than 75% of the total energy consumption of glass production. How to reduce the energy consumption of glass kilns has become the key to energy saving in glass production. The f··· ...

-

17

2024-12

The kiln is the heart of a glass factory, and its operation is directly related to the product quality and economy of the factory. In recent years, with the introduction of many new energy-saving technologies for kilns abroad, my country's glass kilns have improved in structu··· ...

-

17

2024-12

Silica bricks for glass kilns refer to silica refractory products used in high-temperature parts of glass kilns (not in contact with glass liquid). Glass kilns are complex and large masonry built of various refractory materials, and their vaults are mostly made of silica bricks. ··· ...

-

17

2024-12

The main difference between zircon mullitebrick and sintered zirconium corundum brick (i.e. sintered AZS brick) lies in their chemical composition, microstructure, and the resulting performance differences. Here are some key differences between the two: Chemical composition:zirco··· ...

-

17

2024-12

1. Sand mold making:The sand mold is made of silica sand and water glass as a binding agent. After the water glass and silica sand are mixed evenly in a mixer, a support box is installed according to the model requirements to start making the sand mold, and then it is loaded on t··· ...

-

16

2024-12

1. Fused alumina zirconium silica brick (AZS)Fused AZS bricks are are divided into 3 grades according to the content of zirconium: 33%, 36% and 41%. The zirconium corundum bricks used in the glass industry contain 50%~70% Al₂O₃ and 20%~40% ZrO₂. The density is 3.4~4.0g/cm³, t··· ...

Wechat Us

Wechat Us