Properties of silica bricks

2022-04-06

The performance requirements of silica bricks and the appearance of silica bricks are stipulated in the standard as follows: cracks are allowed to cross one edge, and special-shaped and special-shaped bricks with a side width of less than 50mm are allowed to cross two edges. Two points need to be paid special attention to when using silica bricks: when the temperature of silica bricks is between 200~300℃ and 573℃, due to the transformation of crystal form, the volume suddenly expands. Severe temperature changes should be avoided.

The softening temperature of silica brick under load is as high as 1640~168O℃, and the volume is relatively stable in long-term use at high temperatures. However, the thermal shock resistance of silica brick is poor, and the refractoriness is not high enough.

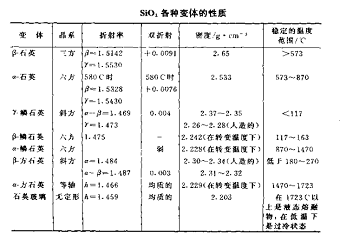

The main component of silica brick is SiO2. SiO2 has 7 variants and 1 phenanthrene crystal variant under normal pressure, namely β-quartz, α-quartz, γ-tridymite, β-tridymite, α-tridymite, β-cristobalite, α-cristobalite and quartz glass. The properties of its variants are shown in the table below.

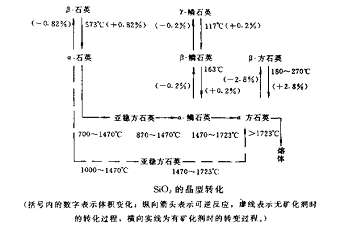

SiO2 undergoes crystal transformation when heated, and its process, temperature, and volume changes are shown in the following figure.

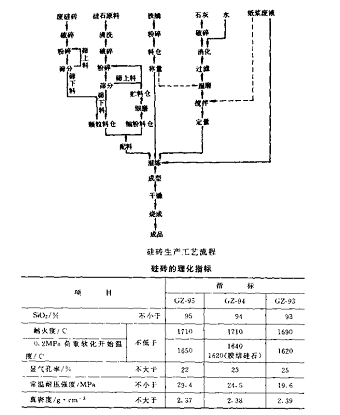

The production process of silica brick is shown in the figure below.

Silica brick undergoes a phase change during the firing process, so the heating rate should be controlled during the firing process. Below 600℃, the heating rate is 20℃/h, 600~1100℃, the heating rate is 25℃/h, 1100~1300℃, the heating rate is 10℃/h, 1300~1350℃, the heating rate is 5℃/h, 1350~143O℃, the heating rate is 2℃/h.Severe temperature changes should be avoided; contact with alkaline slag should be avoided as much as possible.

The Chinese standard (GB/T26081987) divides silica bricks into three grades: GZ-95, G2-94, and GZ-93 according to physical and chemical indicators. Its physical and chemical indicators and size tolerances are listed in the following table.

The appearance of silica bricks in the standard is stipulated as follows: cracks are allowed to cross one edge, and cracks are allowed to cross two edges on the surface of special-shaped and special-shaped bricks whose side width is less than 50mm.

The depth of the missing corner of the pad brick and the supporting brick is not allowed to be greater than 10mm, the depth of the missing edge is not allowed to be greater than 8mm, and the diameter of the molten hole is not allowed to be greater than 10mm. For transverse cracks with a width of 0.11~0.50mm on the brick surface, the length is allowed not to exceed 50mm.

The cross-section spalling of silica bricks is specified as follows:

(1) The top bricks of open-hearth furnaces are not allowed to have surface spalling;

(2) When the crack width of other bricks is not more than 0.1mm, the length is not limited;

(3) When the crack width of other bricks is 0.11~0.25mm, the length is not more than 50mm;

(4) When the crack width of other bricks is 0.26~0.50mm, the length is not more than 30mm;

(5) When the width of other brick cracks is greater than 0.5mm, it is not allowed;

(6) When the cross-section spalling extends to the surface of the brick, it is not allowed.

Relevant information

-

Silicate fire brick

Silicon thermal insulation refractory brick refers to the thermal insulation refractory products made of silica as the main raw material, with a SiO2 content of no less than 91%. In addition to the heat insulation perfor··· -

silica bricks manufacturing process

1.1 Determination of raw material ratio and particle compositionThe raw materials for making silica bricks are silica and waste bricks containing more than 96% SiO2, in addition to lime, mineralizers and organic binders.··· -

Alumina hollow ball bricks

Alumina hollow ball bricks are made of alumina hollow balls and alumina powder as the main raw materials, combined with other binders, and fired at a high temperature of 1750 degrees. It belongs to a kind of ultra-high t··· -

Anti-stripping high alumina brick for cement kiln

Anti-stripping high alumina bricks are made of high alumina bauxite clinker, mullite, kyanite, zircon sand, and binder first through granulation and powdering processes, mixed in a certain proportion, then pressed into s···