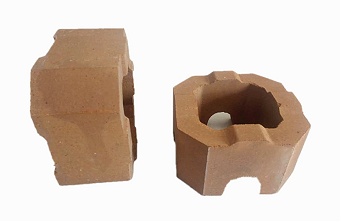

Three key parameters to improve the service life of magnesia bricks

High-purity magnesia bricks are the structural material of high-temperature furnace lining, and their service temperature can reach 2200 ℃. However, the sand purity and properties of high-purity magnesia bricks need to be carefully balanced when applied under such conditions, such as in ultra-high temperature environments in carbon black reactors. We know that refractories (including magnesia bricks) are not only resistant to high temperatures and corrosion/erosion, but they must also be used as little as possible. It is generally believed that the purity of magnesia bricks, the porosity of physical properties, and the size of periclase grains are the key parameters to improving the service life of high-purity magnesia bricks.

A. Purity of magnesia bricks

The MgO content in magnesia brick is an important indicator of magnesia quality. However, it is not enough to use the MgO content as an evaluation criterion. The relative content of impurities, especially those components that are prone to melt formation under high-temperature conditions, is also important. Among the impurity components, the first is B2O3 and SiO2, followed by Al2O3, Fe2O3, MnO, and CaO. Their influence not only depends on their content but especially the influence of each component on the quality of magnesia should also be evaluated according to the ratio of CaO/SiO2, usually, It is desirable to have a high CaO/SiO2 ratio in magnesia for optimum high-temperature performance.

B. Density (porosity) of magnesia bricks

The relative density μ of the refractory material has the following relationship with the porosity ε:

ε=1-μ

This indicates that materials with low porosity have high density, so porosity is a measure of material density.

C. periclase grain size of magnesia bricks

The erosion of periclase grains is initiated by foreign components (substances) at the interface. Therefore, the calcite grains increase and the specific surface area is correspondingly reduced. It can be seen that increasing the grain size of periclase reduces the erosion tendency of magnesia refractories, indicating that coarse-grained sintered magnesia has the advantage of high erosion resistance.

Through the above analysis, it can be considered that special high-purity magnesia refractory products produced by selecting high-quality magnesia with a purity of 98.5%-99% MgO, a bulk density greater than 3.35g/cm3, and a periclase grain size of 50μm to 200μm can be combined with carbon black. The operating conditions of the ultra-high temperature (2100°C) area in the reverse synthesizer are suitable, and the high temperature (1725-1925°C) area is lined with 97.5%~98% MgO magnesia refractory bricks.

-

Silicate fire brick

Silicon thermal insulation refractory brick refers to the thermal insulation refractory products made of silica as the main raw material, with a SiO2 content of no less than 91%. In addition to the heat insulation perfor··· -

silica bricks manufacturing process

1.1 Determination of raw material ratio and particle compositionThe raw materials for making silica bricks are silica and waste bricks containing more than 96% SiO2, in addition to lime, mineralizers and organic binders.··· -

Alumina hollow ball bricks

Alumina hollow ball bricks are made of alumina hollow balls and alumina powder as the main raw materials, combined with other binders, and fired at a high temperature of 1750 degrees. It belongs to a kind of ultra-high t··· -

Anti-stripping high alumina brick for cement kiln

Anti-stripping high alumina bricks are made of high alumina bauxite clinker, mullite, kyanite, zircon sand, and binder first through granulation and powdering processes, mixed in a certain proportion, then pressed into s···