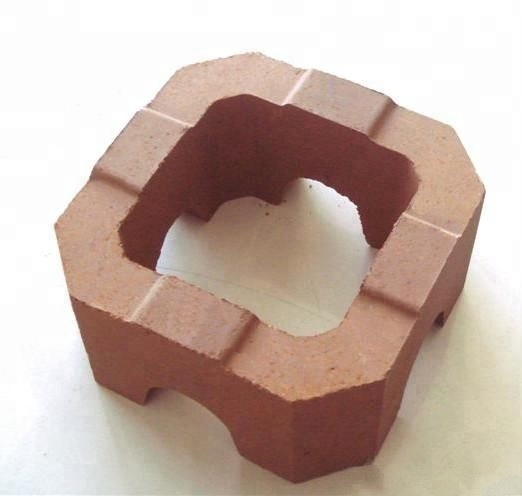

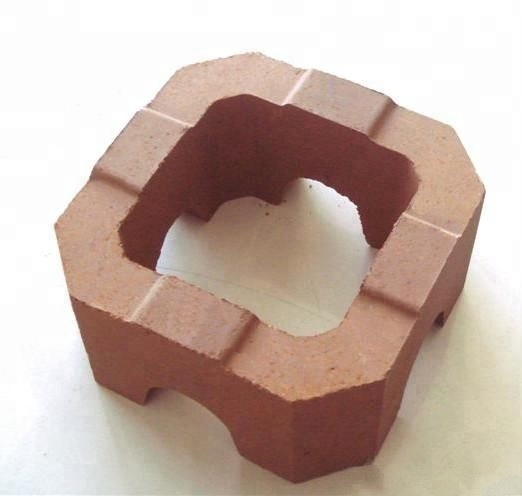

Refractory magnesia brick for glass kiln

Model Number: Hongtai

Certification: ISO9001

Minimum Order Quantity: 1 Ton

Refractory magnesia brick for glass kiln

Magnesite brick is an alkaline refractory with over 90% magnesium oxide content and the main crystalline phase is Magnesite.Generally can be divided into sintered magnesia brick (also known as burned magnesia brick) and chemical bonding magnesia brick (also known as not burned magnesia brick) two categories.The high purity and sintering temperature of magnesia brick, due to the direct contact of magnesite grains, known as direct bonding magnesia brick;The brick made from electrofused magnesia is called electrofused rebonded magnesia brick.

Magnesium brick has high refractoriness, good alkaline slag resistance, high initial temperature of softening under load, but poor thermal shock resistance.Sintered magnesia brick is made of magnesia brick as raw material, after crushing, batching, mixing and molding, it is fired at a high temperature of 1550 ~ 1600℃, and the sintering temperature of high purity products is above 1750℃.Unpoured magnesia brick is made by mixing, forming and drying with appropriate chemical binder in magnesia.

Features:

high temperature strength,

high temperature volume stability

strong slag resistance

high refractoriness

Magnesium bricks • Instructions for use

It is mainly used for basic open hearth furnace, electric furnace bottom and wall, permanent lining of oxygen converter, non-ferrous metal smelting furnace, high temperature tunnel kiln, calcined magnesia brick and lining of cement rotary kiln, furnace bottom and wall of heating furnace, lattice brick of regenerative chamber of glass kiln, etc.

Magnesium brick • production process

Sintered magnesia brick is made of magnesia brick as raw material, after crushing, batching, mixing and molding, it is fired at a high temperature of 1550 ~ 1600℃, and the sintering temperature of high purity products is above 1750℃.Unpoured magnesia brick is made by mixing, forming and drying with appropriate chemical binder in magnesia.

Chemical indicators

| Index | MZ-89 | MZ-91 | MZ-95 | MZ-97 |

| MgO % ≥ | 89 | 91 | 94.5 | 96.5 |

| CaO % ≤ | 3 | 2.5 | 2.0 | 1.5 |

| Apparent Porosity % ≤ | 20 | 18 | 17 | 16 |

| Cold Crushing Strength Mpa ≥ | 50 | 60 | 65 | 70 |

| 0.2Mpa Initial Soften Temperature | 1540 | 1550 | 1620 | 1700 |

| Reheating linear change (%) 1650 C 2h | 0.6 | 0.5 | 0.4 | 0.4 |

Production capacity: Our factory actively response to government environmental protection policy, we designed and built the fully automatic controlled high temperature gas tunnel kiln (1700℃), and got capacity of annual output 70,000 tons of high quality refractory products.

Packing details:

★Bricks: Fumigated wooden pallet with log paperboard covered and stainless steel band strapping, the whole outside is wrapped with thermoplastic film. Or carton packaging.

★Wooden pallet size: usually 92*92cm (standard brick)

★Castable: Ton bag with rain film and 25kg bags inside

★Or according to customer’s requirements

Transportation

★Port of dispatch: Tianjin port; Qingdao port

★Delivery time: According to customer’s demand or two sides negotiate

We provide you

★Timely response: Timely response to your inquiry within 24 hours and provide solution.

★Competitive Price: Make the products competitive in your market.

★Free sample: Free sample are offered, trial order are accepted for quality evaluation.

★Strict quality control: We set Quality Management System, from the raw material to finished products, produce high quality products according to chemical & physical specifications strictly to satisfy customers’ needs.

★Fast delivery time: Within 3-30 days according to your quantity after receiving your advance payment.

★ Professional services: Provide pictures from order to delivery. Inspect report by our country’s designated authority and oversea services if necessary.

We are here for you!

Certification: (ISO 9001:2015)

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours..