Graphite Electrode

Model Number: hongtai

Certification:

Minimum Order Quantity:

Introduction to graphite electrodes

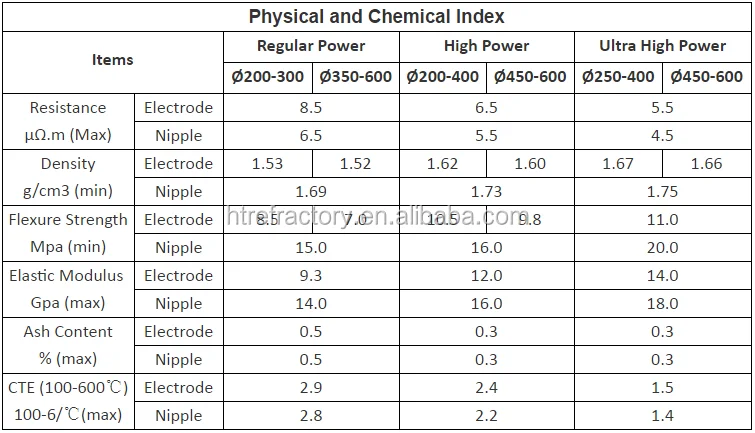

Graphite electrode, mainly made of petroleum coke and needle coke, coal tar pitch as binder, calcined, compounded, kneaded, pressed, calcined, graphitized, machined, is released in the form of electric arc in electric arc furnace The conductor that heats and melts the charge of the electric charge can be divided into ordinary power, high power and ultra high power according to its quality index.

Graphite electrode • Instructions for use

1. Damp graphite electrodes should be dried before use.

2. Remove the foam protective cap on the spare graphite electrode hole and check whether the internal thread of the electrode hole is complete.

3. Clean the surface of the spare graphite electrode and the internal thread of the hole with compressed air without oil and water; avoid cleaning with steel wire or metal brush.

4. Carefully screw the joint into the electrode hole of the end of the spare graphite electrode (it is not recommended to directly insert the joint into the electrode removed from the furnace). Do not hit the thread.

5. Screw the electrode spreader (a graphite spreader is recommended) into the electrode hole at the other end of the spare electrode.

6. When lifting the electrode, pad the soft material to the underside of the end of the spare electrode fitting to prevent the ground from damaging the joint; lift the lifting ring with the hook into the lifting ring of the spreader, and lift the electrode to be stable to prevent the electrode from being loosened by the B end. Take off or collide with other fixtures.

7. Hang the spare electrode above the electrode to be connected, and then slowly drop it after aligning the electrode hole; rotate the spare electrode to rotate the screw hook together with the electrode; when the distance between the two electrode ends is 10-20mm, use compressed air again. Clean both ends of the electrode and the exposed part of the joint; when the electrode is completely lowered at the end, it should not be too strong, otherwise the electrode hole and the thread of the joint will be damaged due to the violent collision.

8. Screw the spare electrode with a torque wrench until the end faces of the two electrodes are in close contact (the correct connection between the electrode and the joint is less than 0.05 mm).

Graphite is very common in nature, and graphene is the most intensely known substance in humans, but scientists may still have to spend years or even decades to find a way to convert graphite into large pieces of high-quality graphene "film". The methods that can be used to make a variety of useful substances for humans. According to scientists, graphene has a unique set of properties in addition to its exceptionally strong properties. Graphene is currently the most well-known material for electrical conductivity, which makes it a potential application in the field of microelectronics. Researchers have even seen graphene as a replacement for silicon that can be used to produce future supercomputers.

Graphite electrode ? production process

The petroleum coke and needle coke are used as raw materials, and the coal bitumen is used as a binder, which is prepared by calcination, compounding, kneading, pressing, roasting, graphitization and machining.

Production capacity: Our factory actively response to government environmental protection policy, we designed and built the fully automatic controlled high temperature gas tunnel kiln (1700℃), and got capacity of annual output 70,000 tons of high quality refractory products.

Packing details:

★Bricks: Fumigated wooden pallet with log paperboard covered and stainless steel band strapping, the whole outside is wrapped with thermoplastic film. Or carton packaging.

★Wooden pallet size: usually 92*92cm (standard brick)

★Castable: Ton bag with rain film and 25kg bags inside

★Or according to customer’s requirements

Transportation

★Port of dispatch: Tianjin port; Qingdao port

★Delivery time: According to customer’s demand or two sides negotiate

We provide you

★Timely response: Timely response to your inquiry within 24 hours and provide solution.

★Competitive Price: Make the products competitive in your market.

★Free sample: Free sample are offered, trial order are accepted for quality evaluation.

★Strict quality control: We set Quality Management System, from the raw material to finished products, produce high quality products according to chemical & physical specifications strictly to satisfy customers’ needs.

★Fast delivery time: Within 3-30 days according to your quantity after receiving your advance payment.

★ Professional services: Provide pictures from order to delivery. Inspect report by our country’s designated authority and oversea services if necessary.

We are here for you!

Certification: (ISO 9001:2015)

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours..