Light weight silica fire brick

Model Number: Hongtai

Certification: CE

Minimum Order Quantity: 5 ton

Professional team sales

light weight silica fire brick for refractory

Introduction to Lightweight Silica Brick

Lightweight silica bricks are also called silica insulation bricks. Lightweight refractory material with silicon dioxide above 91% and bulk density below 1.2g/cm3. The refractoriness and softening temperature under load are not much different from ordinary silica bricks with the same composition. However, due to the many pores, the compressive strength, slag resistance, and corrosion resistance are not as good as ordinary silica bricks, but the thermal shock resistance has been improved.

Raw material of light silica brick

Lightweight silica bricks use finely divided silica as raw materials, and their critical particle size is usually not more than 1mm, and the particles smaller than 0.5mm are not less than 90%. It is prepared by adding flammable substances to the ingredients or adopting the gas generation method to form a porous structure and firing. Can also be made into unburnt products. It is mainly used for all parts of the kiln that requires heat insulation or lightening of its own weight without direct contact with the melt, free from corrosive gas, and not subject to sudden temperature changes. It is used at high temperature and cannot be in contact with alkaline refractory materials. According to different materials, the highest operating temperature is 1200~1550℃.

The mineral composition of light silica bricks

Phosphorite is 78% to 86%, cristobalite is 13% to 15%, and quartz is 4% to 7%. The bulk density is 0.9 to 1.19 g/cm3, the compressive strength is 2.0 to 5.9 MPa, and the thermal conductivity is 0.35 to 0.42 W·(m·K). It has excellent fire resistance. Its softening temperature under load is close to 1620℃ for dense silica bricks, with only a small residual expansion, and its thermal stability is better than dense silica bricks.

The technical indicators of light silica bricks

| Brand | GGR-1.0 | GGR-1.1 | GGR-1.15 | GGR-1.2 | |

| SiO2% | ≥ | 91 | 91 | 91 | 91 |

|

Refractoriness under load of 0.1Mpa °C |

≥ | 1400 | 1420 | 1500 | 1520 |

| Bulk Density (g/cm3) | ≤ | 1 | 1.1 | 1.15 | 1.2 |

| Refiring line changes % | 1550°C*2h | 0.5 | 0.5 | ||

| 1450°C*2h | 0.5 | 0.5 | |||

| Cold Crushing Strength (Mpa) | ≥ | 2 | 3 | 5 | 5 |

|

Thermal conductivity coefficient (350±25℃)/W/m.k |

≤ | 0.55 | 0.5 | 0.65 | 0.7 |

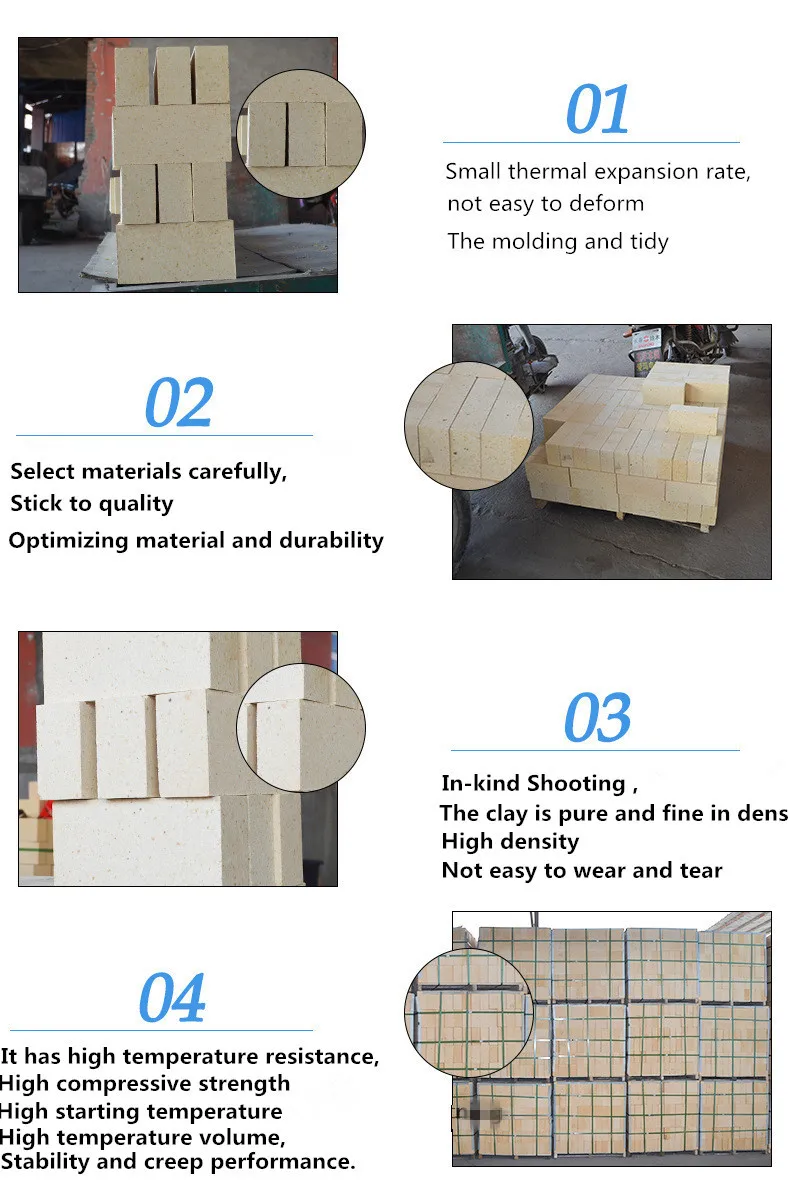

Product Features

Features and application of light silica brick

Lightweight silica bricks generally use crystalline quartzite or silica sand as raw materials, and add flammable materials such as coke, anthracite, sawdust, carbonized rice husk or gas foaming to form a porous structure. The refractoriness and softening temperature under load are not much different from ordinary silica bricks with the same composition. However, due to many pores, the compressive strength, slag resistance, and corrosion resistance are not as good as ordinary silica bricks.

Application of Light Weight Silica fire Brick

Generally Light Weight Silica fire Brick can be divided into two levels: the first grade can be used in the top of the steel rolling furnace and the silicate industrial kiln roof, and can be directly in contact with the flame; the second grade is used in the general industrial kiln Insulation. Applicable to: industrial furnaces such as coke ovens, hot blast furnaces, glass melting furnaces and carbon calciners. It has excellent fire resistance. Its softening temperature under load is close to 1620℃ for dense silica bricks, with only a small residual expansion, and its thermal stability is better than dense silica bricks. Therefore, siliceous heat insulating refractory bricks can be used for a long time under high temperature conditions (1500-1550°C) without contact with molten slag, but they are especially suitable for high temperature hot blast furnaces of large blast furnaces. Thermal insulation of silica brick gas.

Technical conditions for Light Weight Silica fire Brick used in glass kilns

Lightweight silicon insulation brick is a kind of heat insulation refractory with the content of SiO2 not less than 91%, which is mainly made of silica.Lightweight silica insulating brick volume density of 0.9 ~ 1.1 g/cm3, thermal conductivity is only half of ordinary silica brick, good thermal shock resistance, the rul start temperature can reach 1600 ℃, far above the clayey insulating brick.Thus the siliceous insulating brick highest use temperature is 1550 ℃.It doesn't contract at high temperatures and even dips slightly.

Refractory fire light weight Light Weight Silica fire Brick are usually made from crystalline quartzite and contain inflammable materials, such as coke and anthracite sawdust, or form porous structures by gas foaming.Similar to the production industry of ordinary silica bricks, some mineralized agents (CaO, Fe2O3) were added into the ingredients to promote the transformation of quartz, and the strength of the bricks was obtained by using the waste pulp as the binder.When coke or anthracite is used as fuel, because ash is carried into Fe2O3 and Al2O3, no additional iron phosphorus is added to the mix.Lightweight silica brick firing, should maintain strong oxidizing flame before 1200 ℃, make join completely burn out.

Production capacity: Our factory actively response to government environmental protection policy, we designed and built the fully automatic controlled high temperature gas tunnel kiln (1700℃), and got capacity of annual output 70,000 tons of high quality refractory products.

Packing details:

★Bricks: Fumigated wooden pallet with log paperboard covered and stainless steel band strapping, the whole outside is wrapped with thermoplastic film. Or carton packaging.

★Wooden pallet size: usually 92*92cm (standard brick)

★Castable: Ton bag with rain film and 25kg bags inside

★Or according to customer’s requirements

Transportation

★Port of dispatch: Tianjin port; Qingdao port

★Delivery time: According to customer’s demand or two sides negotiate

We provide you

★Timely response: Timely response to your inquiry within 24 hours and provide solution.

★Competitive Price: Make the products competitive in your market.

★Free sample: Free sample are offered, trial order are accepted for quality evaluation.

★Strict quality control: We set Quality Management System, from the raw material to finished products, produce high quality products according to chemical & physical specifications strictly to satisfy customers’ needs.

★Fast delivery time: Within 3-30 days according to your quantity after receiving your advance payment.

★ Professional services: Provide pictures from order to delivery. Inspect report by our country’s designated authority and oversea services if necessary.

We are here for you!

Certification: (ISO 9001:2015)

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours..